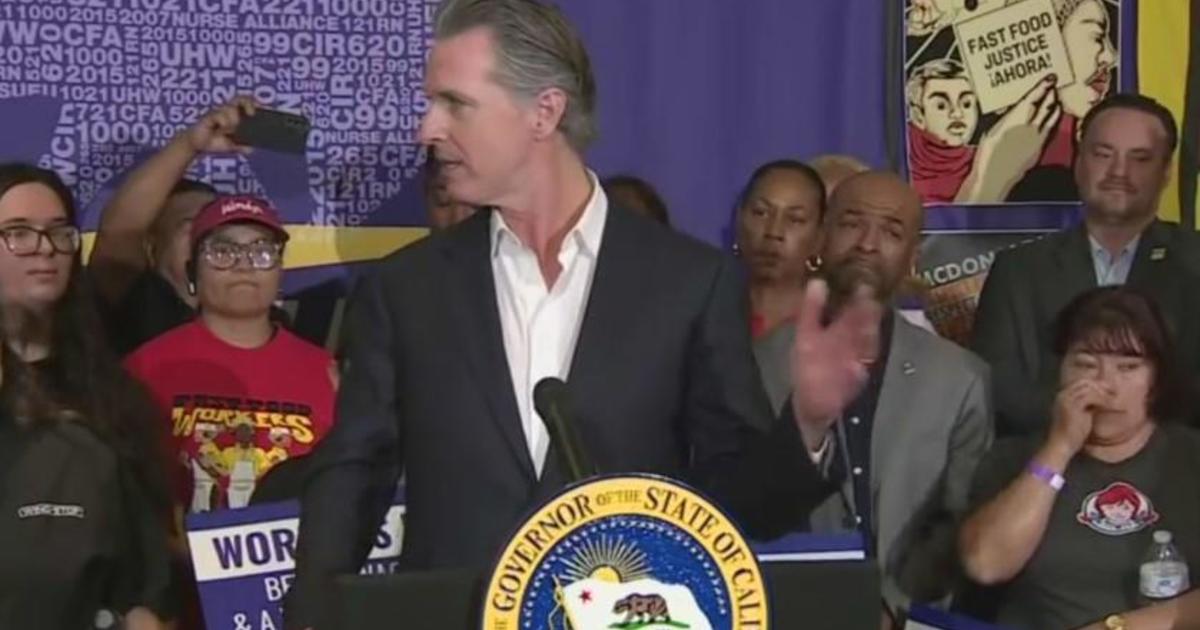

California fast food workers will be paid at least $20 per hour next year under a new law signed Thursday by Gov. Gavin Newsom.

When it takes effect on April 1, fast food workers in the state will have among the highest minimum wages in the country, according to data compiled by the University of California-Berkeley Center for Labor Research and Education. The state’s minimum wage for all other workers is at $15.50 per hour and is already among the highest in the nation.

Newsom’s signature on Thursday reflects the power and influence of labor unions in the nation’s most populous state, which have worked to organize fast food workers in an attempt to improve their wages and working conditions.

The “automated” stores are less about reduction in labor cost and more about improving the overall operation and growing sales (thus increasing jobs.) It does help labor cost because the labor that is staffed is more efficient, but that’s more of a tertiary outcome. They still employ roughly the same number of staff, and potentially will employ even more as efficiency of the process grows.

Simplest way I can explain this is thinking about the order kiosks. One of the worst parts of fast food is that most people aren’t actually trained at birth how to order right, and secondarily it introduces another couple of humans who are fallible and won’t get it correct. EG: customer comes into McDonald’s and says “I want the whopper basket.” Crew person, internal: “wtf are they talking about, I guess I’ll give them a big mac.” Then the customer comes back pissed off because they actually wanted a quarter pounder with fries, it has to be remade distracting the kitchen, manager, that crew person, etc further.

Also, the entire time the customer is ordering, it’s engaging a whole crew person. To scale up and take more orders, you have to add an additional crew person for each order you want to take concurrently, and because customer flow is not 100% predictable, this isn’t even really possible. Most McDonalds have like 4 kiosks, and you’ll only find that they’re all used at the same time for maybe a grand total 3-4 hours a day. To replicate that with a human, you would have to be like “I need you to work from 7:23-7:59, and you to work 11:46-12:07, and you to work, 12:03-12:07…” which literally no one is going to do, and isn’t actually that predictable regardless. No automation means some customers are going to come in, see a line, and peace out. This means lower sales, and lower overall employees.

With automation, the demand can be filled much more often and a whole massive point of complexity is removed. In the example above, the customer comes in wanting a whopper basket, looks at the menu and goes “oh they call it a quarter pounder here” and clicks the buttons. Because they can now capture more demand, kitchens are busier and there are more orders to deliver, so they move that person who was going to be extremely inefficient by comparison serving customers 1:1, and move them to a kitchen position or to an expo position.)

Found the robot sales person

read the post and reply like a person.

You lost all credibility when you said it was “less about the costs”

I recently hired a mid -level manager from McDs strategy team and it’s at least 90% about cost reduction. They’re watching the adoption curve, because older and urban demographics still mostly order at the counter and refuse to use the self ordering lines. That’s why they offer free fries and free upgrades at select locations for using self ordering to force the greater adoption.

Also they’ve started reducing headcount in locations where adoption is higher, but still limit hours to hourly workers.

It’s all right there if you want to believe it, but good luck with the spin.

Wouldn’t kitchens be the next point of automation?

I mean, they’re definitely working on it, but so far it’s tech that isn’t ready. also, it’s still a similar problem, at least for now. The thing I’ve heard about is automated french fry machines. Basically, a big fryer that places fries into the fryer, and then transfers them to the bagging station. From what I’ve heard, they’re very expensive and don’t work well. But the strategy there is more around improving human foibles - estimating the amount of fries needed for rushes more accurately, etc. The person is still there working the station, but assisted by tech. Also improving capacity. That one person that is supposed to be doing all of the things now has less to do, and so can focus on making sure orders of fries are ready to be bagged by expo people. This means they’re bottlenecked less often, can serve more customers, and thus hire more staff.

I mean, make no mistake, we’re headed towards a mostly automated future for these types of jobs, most likely. Tech will improve, get cheaper, etc. But this has been the way things have been for the last 20-30 years. Watch a drive through in most mcdonalds and they have a machine that makes drinks. Before that, having a machine that dispensed fries into the basket was a luxury. Even the grill being like a big panini press was an innovation. So far, this has all led to more jobs. In the case of fast food, just producing consistent results quickly has led to growth. I’d check out youtube or ticktok. I think McDonald’s even puts out a lot of videos these days showing what’s really happening in the kitchen. It’s a little bit fascinating.

I stopped reading when you said automation increases jobs. But cool story, bro.

You might want to check out, uh, history. It’s rife with “omg this new technology is scary and bad” like the cotton gin, or more recently, computers.

You might want to read a little deeper. Technology always removes jobs. People shift to new jobs. The unknown is if new jobs will exist or if we’re entirely post scarcity.

this is why, famously, there stopped being jobs with the introduction of the wheel.

But when will we finally be free of the pages upon pages of job listings for stable boys. Who will care for all the horses?!